In factory or production site product and material transportation, electric vehicles have a long history of application. Around 1910, electric vehicles were already being used for cargo transport, and in 1922, electric lifting forklifts appeared. Subsequently, electric vehicles, particularly those powered by advanced battery packs, became widely used in factories for lifting, moving, and stacking goods.

These versatile machines have revolutionized material handling processes across industries, offering numerous advantages over their internal combustion counterparts. The evolution of battery packs technology has been instrumental in their increased adoption, providing more efficient, longer-lasting power sources that enhance operational productivity.

Today, electric forklifts represent a significant portion of material handling equipment in modern industrial facilities, with continuous advancements in battery packs and motor technology driving their performance capabilities to new heights.

A Rich History of Electric Material Handling

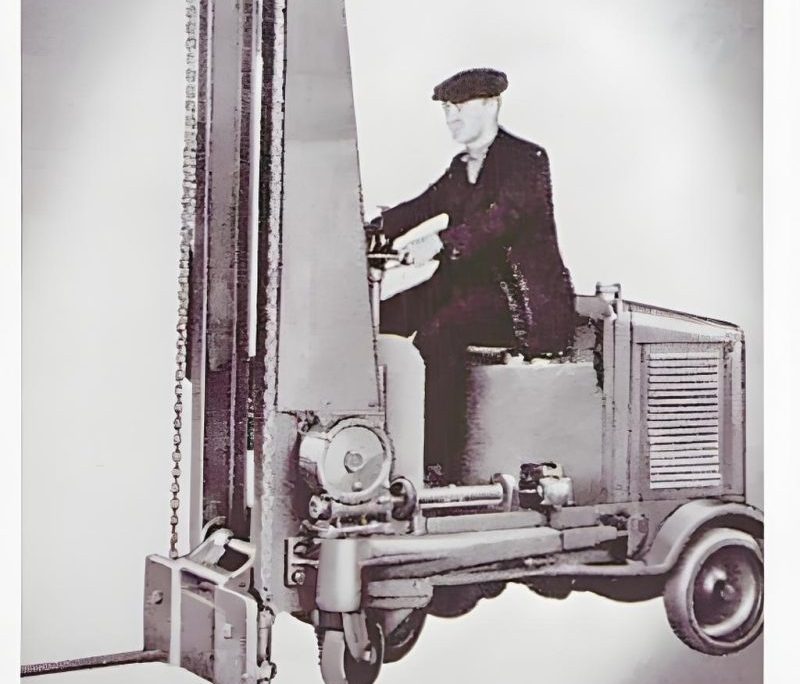

The history of electric forklifts dates back over a century, with the first electric vehicles appearing around 1910 for basic cargo transport. These early models were primitive compared to today's sophisticated machines but laid the groundwork for future innovations.

In 1922, a significant milestone was reached with the introduction of the electric lifting forklift, which combined mobility with vertical lifting capabilities. This breakthrough revolutionized warehouse operations and set the stage for the widespread adoption of electric material handling equipment.

Throughout the 20th century, advancements in battery packs technology drove continuous improvements in electric forklift performance. From the early lead-acid batteries to modern lithium-ion battery packs, each innovation extended operating times, reduced charging periods, and increased overall efficiency.

Types of Electric Forklifts

Counterbalanced Forklifts

Available in both three-wheel and four-wheel configurations, these forklifts use a counterweight at the rear to balance loads. They are highly maneuverable and suitable for a wide range of indoor applications.

Modern counterbalanced models feature advanced battery packs that provide extended operating hours, making them ideal for full-shift operations without mid-shift recharging.

Reach Trucks

Designed for narrow aisle applications, reach trucks feature an extending mast that allows them to reach loads stored at height while maintaining a small footprint.

Their compact design combined with efficient battery packs makes them perfect for high-density storage facilities where space is at a premium.

Order Pickers

These specialized forklifts allow operators to access individual items from racking without removing entire pallets. They feature a platform that elevates the operator to the level of the goods.

The latest order pickers incorporate lightweight yet powerful battery packs that optimize energy usage while providing sufficient power for a full day's operation.

Three-way Stackers

Featuring a mast that can rotate 180 degrees, three-way stackers excel in very narrow aisle applications, allowing for high-density storage and retrieval of palletized goods.

Their efficient power management systems, paired with high-capacity battery packs, ensure they can operate continuously through demanding shift schedules.

Pallet Trucks

These essential warehouse tools are designed for moving palletized goods over short distances. Electric pallet trucks reduce operator fatigue compared to manual models.

Modern electric pallet trucks use compact, high-performance battery packs that provide ample power while maintaining a low profile for easy maneuverability under pallets.

Specialized Models

A variety of specialized electric forklifts exist for unique applications, including those designed for cold storage, clean rooms, and hazardous environments.

These specialized units often feature modified battery packs designed to perform in extreme conditions, such as the low temperatures found in freezer warehouses.

Key Components of Electric Forklifts

Power System

The power system is the heart of any electric forklift, consisting primarily of the battery packs, charger, and related electrical components. The battery packs provide the energy required for all operations, from propulsion to lifting functions.

Modern systems incorporate smart technology to monitor battery packs performance, optimize energy usage, and provide operators with real-time information about remaining charge levels.

Chassis

The chassis forms the structural foundation of the forklift, supporting all other components. It includes the frame, wheels, steering mechanism, and braking system. Electric forklift chassis are specifically designed to accommodate the weight and placement of battery packs.

The design ensures optimal weight distribution, stability, and maneuverability while supporting the unique characteristics of electric propulsion systems.

Working Components

This section includes the mast, forks, and lifting mechanisms that enable the forklift to raise and lower loads. Electric hydraulic systems power these components, drawing energy from the battery packs to operate pumps and cylinders.

The working components are engineered for precision, allowing operators to handle loads with accuracy while minimizing energy consumption.

Electrical Equipment

This encompasses the electric motors, controllers, wiring, and operator interface systems. The main drive motor and hydraulic pump motor work in concert, regulated by sophisticated controllers that optimize performance based on battery packs condition and operational demands.

Modern electric forklifts feature digital displays that provide operators with essential information about battery packs status, operational modes, and maintenance alerts.

Battery Technology in Electric Forklifts

At present, the batteries mainly used in electric forklifts are still lead-acid batteries, with advanced batteries such as lithium-ion battery packs not yet widely adopted. However, this landscape is rapidly changing as lithium-ion technology becomes more cost-effective and performance capabilities improve.

Lead-acid battery packs have been the industry standard for decades, offering a proven, reliable power source at a relatively low cost. These battery packs are robust, can withstand heavy use, and are fully recyclable, making them an environmentally responsible choice despite their lower energy density compared to newer technologies.

Lithium-ion battery packs represent the future of electric forklift power, providing numerous advantages including higher energy density, faster charging times, longer lifespan, and no memory effect. These advanced battery packs can often complete a full shift on a single charge and can be opportunity-charged during breaks without reducing overall battery life.

The choice between lead-acid and lithium-ion battery packs depends on various factors including initial investment budget, operational requirements, charging infrastructure, and total cost of ownership over the equipment's lifespan. Many operations are making the switch to lithium-ion battery packs as the long-term benefits increasingly outweigh the higher upfront costs.

Advantages of Electric Forklifts

Smooth Operation

Electric forklifts offer smoother acceleration and deceleration compared to internal combustion models, reducing load movement and improving operator control. This smooth operation is made possible by precise motor control systems powered by advanced battery packs.

Easy Maintenance

With fewer moving parts than internal combustion engines, electric forklifts require less maintenance. There's no need for oil changes, filter replacements, or tune-ups, reducing downtime and maintenance costs associated with traditional forklifts.

Simple Operation

Electric forklifts feature intuitive controls that are easier to learn and operate, reducing training time for new operators. The consistent power delivery from modern battery packs ensures predictable performance in all operating conditions.

Lower Operating Costs

Electricity is generally cheaper than fossil fuels, resulting in lower energy costs. When combined with reduced maintenance requirements, electric forklifts typically offer significantly lower total operating costs compared to internal combustion models, especially as battery packs technology improves efficiency.

Environmentally Friendly

In enclosed environments, electric forklifts produce no exhaust emissions and minimal noise, creating a healthier and more pleasant working environment. This makes them ideal for indoor operations where air quality is a concern.

Energy Efficiency

Modern electric forklifts with advanced battery packs convert a higher percentage of energy into useful work compared to internal combustion engines, which waste significant energy as heat. This efficiency translates to lower energy consumption per task.

Considerations for Electric Forklift Implementation

While electric forklifts offer numerous advantages, there are important considerations to keep in mind when implementing them in your operations:

Charging Infrastructure

Electric forklifts require dedicated charging stations for their battery packs. This represents an additional investment in infrastructure, including proper electrical wiring, charging units, and potentially battery packs changing equipment for multi-shift operations.

Higher Initial Investment

Electric forklifts typically have a higher upfront purchase price compared to internal combustion models, primarily due to the cost of battery packs and electric motor systems. However, this investment is often offset by lower operating costs over the equipment's lifespan.

Charging Time Requirements

Traditional lead-acid battery packs require significant charging time (typically 7-8 hours), with additional cooling time needed before reuse. While fast-charging options (2-3 hours) are available for certain battery packs, they may reduce overall battery lifespan if used regularly.

Limited Continuous Operation

A single charge for conventional battery packs provides a limited operating time compared to the continuous operation possible with refueled internal combustion models. This can be mitigated through strategic charging schedules, battery packs swapping systems, or investing in advanced lithium-ion battery packs with longer run times.

Performance Limitations

Due to battery packs capacity and specific power limitations, electric forklifts generally have smaller drive motors than internal combustion engines, resulting in lower speeds and reduced climbing ability. These limitations make them better suited for specific applications rather than all-purpose outdoor use.

Ideal Applications for Electric Forklifts

Warehouses and Manufacturing Facilities

Electric forklifts are particularly well-suited for warehouses and manufacturing facilities with narrow aisles, moderate distances, and lighter load requirements. Their compact design and maneuverability make them ideal for navigating confined spaces.

The controlled environment of indoor facilities also helps extend battery packs life by protecting them from extreme temperatures and weather conditions that can negatively impact performance.

Specialized Environments

In certain special working conditions, electric forklifts become the best choice for goods transportation. This includes operations in flammable goods warehouses or industries with high environmental requirements such as food processing, pharmaceuticals, microelectronics, and instrumentation.

In these environments, the zero-emission operation of electric models powered by sealed battery packs is not just preferred but often mandated by regulatory standards.

Cold Storage Operations

In cold storage warehouses, internal combustion engines face significant starting difficulties due to low temperatures. Electric forklifts excel in these conditions, with specialized battery packs designed to perform reliably even in freezing environments.

The absence of exhaust emissions is also critical in cold storage facilities where ventilation is often limited, making electric models with appropriate battery packs the only viable option.

Distribution Centers

Distribution centers with high-volume, repetitive material handling operations benefit greatly from electric forklifts. The reduced noise levels create a more pleasant work environment, while the lower operating costs contribute to better bottom-line performance.

Many distribution centers are implementing opportunity charging strategies for their battery packs during shift breaks, maximizing equipment utilization throughout the workday.

Other Battery-Powered Industrial Vehicles

Electric Tuggers

Electric tuggers (used for pulling unpowered containers or carriages) are essential in many industrial settings. These versatile machines use powerful battery packs to move heavy loads efficiently without emitting harmful fumes, making them ideal for indoor applications.

Mobile Elevating Platforms

Mobile elevating work platforms provide safe access to high areas in warehouses and facilities. Electric models with advanced battery packs offer quiet operation and precise control, making them suitable for use in noise-sensitive environments and cleanrooms.

Automated Guided Vehicles

Automated guided vehicles (AGVs) are revolutionizing material handling through autonomous operation. These advanced systems rely on reliable battery packs to power their navigation and transport functions, operating 24/7 in many facilities with scheduled charging cycles.

The Future of Electric Forklifts

The future of electric forklifts is closely tied to advancements in battery packs technology. As lithium-ion battery packs become more affordable and energy-dense, their adoption in material handling equipment will continue to accelerate. This transition will bring numerous benefits to industrial operations worldwide.

Emerging battery packs technologies promise even faster charging times, longer operational periods between charges, and extended overall lifespans. These improvements will address many of the current limitations of electric forklifts, making them viable alternatives for more applications previously dominated by internal combustion models.

Additionally, smart battery management systems will become more sophisticated, optimizing energy usage based on specific operations and providing detailed analytics to help facilities managers improve efficiency. Integration with warehouse management systems will enable more intelligent deployment of electric forklifts based on real-time battery packs status and operational needs.

As sustainability becomes an increasingly important consideration for businesses worldwide, the shift toward electric material handling equipment powered by advanced battery packs will accelerate. This transition not only reduces environmental impact but also delivers tangible operational and financial benefits.