The Science of Battery Performance Verification

In today's energy-driven world, accurate Battery Testing is crucial for ensuring safety, reliability, and performance across all applications – from electric vehicles to portable electronics and even battery generator for home systems. This comprehensive guide explores the fundamental principles, evaluation methodologies, and essential equipment that form the backbone of professional battery testing.

The fundamental principles of Battery Testing revolve around evaluating a battery's ability to store and deliver energy under various conditions. These principles apply universally, whether testing large-scale industrial batteries, smaller units used in a battery generator for home setup, or backup power systems for critical infrastructure like optical transceivers in telecommunications networks.

Core Testing Principles

At its essence, battery testing measures electrochemical reactions within cells to determine capacity, efficiency, and longevity. Key principles include understanding charge-discharge cycles, internal resistance, and temperature effects on performance. These principles guide all testing methodologies, ensuring consistent and reliable results across different battery chemistries and applications, including the increasingly popular battery generator for home systems.

Primary Testing Methods

Capacity Testing

Capacity testing determines the total energy a battery can store, typically measured in ampere-hours (Ah) or watt-hours (Wh). This method involves fully charging the battery and then discharging it at a constant current until it reaches its cutoff voltage. For applications like battery generator for home use, accurate capacity measurement ensures the system can provide sufficient power during outages.

The process follows strict protocols to ensure accuracy: standardized temperature conditions (usually 25°C), controlled discharge rates (often C/20 for nominal capacity), and precise voltage monitoring. These standards allow for consistent comparison between different battery models and batches.

Cycle Life Testing

Cycle life testing evaluates how many charge-discharge cycles a battery can undergo before its capacity degrades to a specified threshold (typically 80% of its original capacity). This is particularly important for applications requiring long-term reliability, such as battery generator for home systems that may need to operate for years with minimal maintenance.

Rate Capability Testing

This method assesses a battery's ability to deliver power at different rates, often expressed as a multiple of the nominal capacity (C-rate). A battery with good rate capability can discharge quickly when needed, a critical feature for battery generator for home systems that may need to power multiple devices simultaneously during an outage.

Safety Testing

Safety testing includes a series of evaluations to ensure batteries can withstand extreme conditions without catastrophic failure. This includes overcharge testing, short circuit testing, crush testing, and thermal abuse testing. These tests are vital for all battery applications but especially critical for consumer products like battery generator for home systems where safety is paramount.

Capacity Testing Visualization

A typical charge-discharge curve showing voltage profiles during capacity testing, essential data for evaluating both industrial batteries and battery generator for home systems.

Testing Protocol Steps

- 1 Initial conditioning cycles

- 2 Standard capacity measurement

- 3 Rate capability evaluation

- 4 Cycle life cycling

- 5 Post-test analysis

Cycle life comparison for different battery types, including those suitable for battery generator for home applications.

Environmental Factors in Testing

Environmental conditions significantly impact battery performance and must be carefully controlled during testing. Temperature is particularly critical, as it affects reaction rates within battery cells. Most standard tests are conducted at 25°C, but extended testing often includes evaluations at extreme temperatures (-20°C to 60°C) to simulate real-world conditions.

Humidity control is also important, especially for long-term testing, to prevent corrosion and ensure consistent results. For batteries used in battery generator for home systems, which may be stored in garages or basements with varying conditions, testing across different environmental parameters ensures reliable performance in typical household settings.

Performance Evaluation Dashboard

Modern evaluation systems provide comprehensive data visualization for battery performance metrics, essential for both industrial and battery generator for home applications.

Key Evaluation Metrics

- Energy density (Wh/kg, Wh/L)

- Power density (W/kg, W/L)

- Cycle life (number of cycles)

- Self-discharge rate

- Charge acceptance

- Efficiency (%)

Performance comparison radar chart for different battery technologies, including those used in battery generator for home systems.

动力电池基本测试评价 involves systematic analysis of test data to determine a battery's quality, performance characteristics, and suitability for specific applications. This evaluation process transforms raw test data into actionable insights, whether for high-performance industrial batteries or consumer-oriented products like a battery generator for home system.

Evaluation Criteria Framework

Capacity Retention Analysis

Capacity retention measures how well a battery maintains its storage capacity over time and usage cycles. This is typically expressed as a percentage of the initial capacity. For example, a battery that retains 80% of its original capacity after 1000 cycles is considered to have good longevity.

For battery generator for home applications, capacity retention is particularly important as these systems may undergo relatively few cycles but need to maintain capacity over years of storage. Evaluation involves tracking capacity degradation patterns to predict service life and recommend maintenance schedules.

Efficiency Calculation

Battery efficiency is evaluated in two primary forms: Coulombic (charge) efficiency and energy efficiency. Coulombic efficiency measures the ratio of discharge capacity to charge capacity, while energy efficiency considers the energy output compared to energy input.

Higher efficiency batteries waste less energy as heat, making them more cost-effective and safer. This is especially valuable for battery generator for home systems where energy conversion losses directly impact runtime and operational costs. Efficiency testing must account for different charge-discharge rates and temperature conditions to provide a complete picture.

Rate Capability Assessment

Rate capability evaluation determines how well a battery performs under different discharge rates. This is often presented as a C-rate, where 1C represents discharging the entire battery capacity in one hour. A battery with good rate capability can deliver high power when needed without significant voltage drop or capacity loss.

Safety and Reliability Metrics

Safety evaluation goes beyond pass/fail determinations to quantify risk levels. Metrics include thermal runaway threshold, gas emission profiles during abuse conditions, and recovery capability after over-discharge. For consumer products like battery generator for home systems, these safety metrics are critical for meeting regulatory standards and ensuring user confidence.

Standardized Evaluation Protocols

To ensure consistency across the industry, battery evaluation follows standardized protocols established by organizations such as IEEE, IEC, and UL. These standards define testing procedures, measurement techniques, and performance benchmarks for different battery types and applications.

For example, IEEE 1188 outlines recommended practices for sealed lead-acid batteries, while IEC 62133 specifies safety requirements for lithium-ion batteries in portable applications. Compliance with these standards is essential for market acceptance, particularly for safety-critical applications including battery generator for home systems.

Standardized evaluation allows for meaningful comparison between different battery technologies and manufacturers. This comparability helps engineers select the optimal battery solution for specific applications based on verified performance data rather than marketing claims.

Data Analysis and Reporting

Effective battery evaluation requires sophisticated data analysis techniques to interpret the large volumes of data generated during testing. Modern analysis software can identify performance degradation patterns, predict remaining useful life, and correlate test conditions with performance outcomes.

Comprehensive Reporting Elements

- Test conditions and parameters

- Performance metrics at various stages

- Comparison to industry standards

- Failure analysis (if applicable)

- Recommendations for application suitability

Application-Specific Evaluation

Evaluation must consider the specific application requirements. A battery suitable for a smartphone has different performance characteristics than one designed for an electric vehicle or a battery generator for home system.

For stationary storage applications like battery generator for home use, factors such as deep discharge tolerance, shelf life, and performance at ambient temperatures may be prioritized over weight or volume considerations that are critical for portable devices.

The accuracy and reliability of Battery Testing depend heavily on the quality and capabilities of the testing equipment used. From basic benchtop instruments to sophisticated automated systems, the right equipment ensures precise measurements and repeatable results across all testing scenarios, including quality control for battery generator for home components.

Essential Testing Instruments

Battery Cyclers

Battery cyclers are the workhorses of battery testing laboratories, responsible for controlling charge and discharge processes according to programmed profiles. These sophisticated instruments can apply constant current, constant voltage, or complex pulsed profiles while precisely monitoring voltage, current, and temperature.

Modern cyclers offer channel expansion capabilities, allowing simultaneous testing of multiple cells or packs – a feature that significantly speeds up testing throughput. For evaluating battery generator for home systems, cyclers with higher current capabilities are necessary to simulate the power demands of household appliances.

Environmental Chambers

Environmental chambers control temperature, humidity, and sometimes atmospheric composition during testing. These controlled environments ensure that battery performance data is collected under consistent conditions and allow evaluation of how environmental factors affect battery behavior.

For testing batteries intended for battery generator for home use, chambers can simulate the temperature fluctuations a system might experience in different seasons or geographic locations, providing valuable data on real-world performance expectations.

Impedance Analyzers

Electrochemical impedance spectroscopy (EIS) equipment measures a battery's internal resistance across a range of frequencies. This valuable data helps evaluate electrode performance, electrolyte conductivity, and interface characteristics within the battery.

Impedance analysis provides insights into battery health and degradation mechanisms that aren't visible through simple capacity testing. For battery generator for home systems, impedance testing can predict how well a battery will perform under different load conditions over time.

Safety Testing Equipment

Safety testing requires specialized equipment to evaluate battery response to abuse conditions. This includes crush testers, impact testers, thermal chambers for abuse testing, and gas emission analysis systems.

For consumer products like battery generator for home systems, safety testing equipment must verify compliance with international standards, ensuring protection against fire, explosion, and chemical hazards during normal use and under fault conditions.

Advanced Testing Systems

Modern battery testing has evolved beyond standalone instruments to integrated systems that combine multiple testing capabilities with advanced data acquisition and analysis. These automated systems can run complex test sequences unattended, significantly increasing laboratory productivity.

For large-scale testing facilities and manufacturers of battery systems like battery generator for home products, these integrated systems provide the consistency and throughput needed for quality control and performance validation of production units.

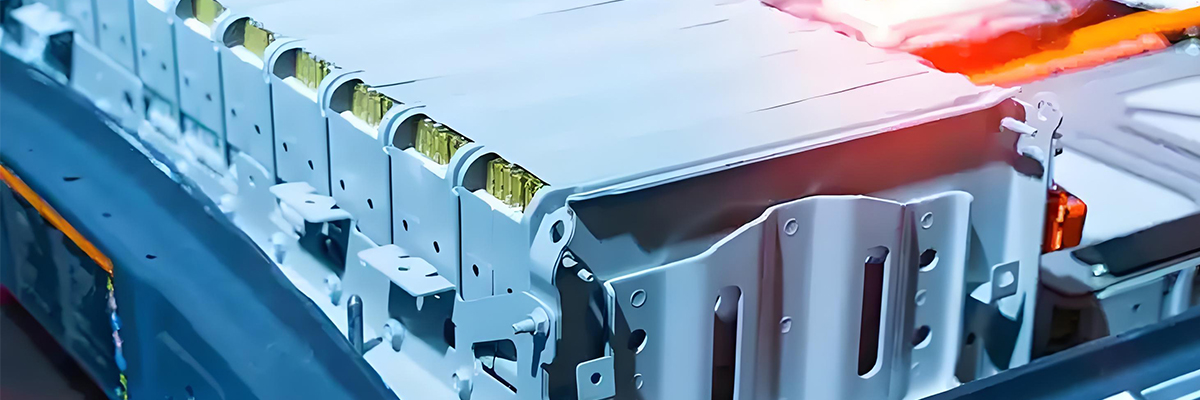

Battery Testing Laboratory

A fully equipped testing facility with cyclers, environmental chambers, and analysis equipment used for evaluating batteries, including those in battery generator for home systems.

Equipment Specifications

Battery Cyclers

Voltage range: 0-60V, Current range: 0-500A, Resolution: 0.1mV, 1mA

Environmental Chambers

Temperature range: -70°C to +180°C, Humidity: 10-98% RH

Impedance Analyzers

Frequency range: 10μHz to 3GHz, Accuracy: ±0.05%

Safety Testers

Crush force: up to 200kN, Impact velocity: 5-15m/s

Equipment Selection Considerations

- Testing range and accuracy requirements

- Throughput and channel count

- Software capabilities and data analysis

- Compliance with industry standards

- Expandability for future needs

- Application-specific requirements (e.g., for battery generator for home testing)

Calibration and Maintenance

Regular calibration is essential to maintain measurement accuracy. Accredited laboratories follow strict calibration schedules traceable to national standards.

Preventive maintenance programs minimize downtime and ensure consistent performance. For critical applications like battery generator for home certification testing, equipment validation is performed before each test series.

Specialized Testing Setups

Pack-Level Testing Systems

For evaluating complete battery packs rather than individual cells, specialized pack-level testing systems are required. These systems handle higher voltages and currents while monitoring multiple cells simultaneously.

Pack testing includes evaluating battery management system (BMS) functionality, cell balancing performance, and overall system efficiency. This is particularly relevant for battery generator for home systems, which typically use multiple cells configured in packs to achieve the required voltage and capacity.

Real-World Simulation Equipment

Advanced testing facilities use equipment that simulates real-world operating conditions. This includes programmable load banks that replicate the power demands of specific applications and environmental simulators that create temperature and humidity profiles.

For battery generator for home testing, this might involve simulating typical household power consumption patterns, including peak loads from appliances like refrigerators, air conditioners, and lighting systems.

Advancing Battery Technology Through Rigorous Testing

The field of Battery Testing continues to evolve alongside battery technology, with new methods and equipment constantly emerging to meet the demands of increasingly sophisticated applications. From fundamental research to production quality control, rigorous testing ensures that batteries deliver on their performance promises while maintaining the highest safety standards.Electronic shelf labels.

As energy storage becomes more prevalent in everyday life – from electric vehicles to battery generator for home systems – the importance of comprehensive testing will only grow. By adhering to established principles, employing robust evaluation methodologies, and using advanced testing equipment, the industry can continue to innovate while ensuring reliability and safety for all users.Related Hydraulic Spare Parts.