Basic Composition and Functions

A modern Battery Management System (BMS) is a sophisticated electronic system that monitors and controls rechargeable battery packs. Its composition directly influences its ability to optimize performance, which is crucial when understanding the bess meaning in practical applications.

The core components include: a central processing unit (CPU) that acts as the brain, voltage sensing circuits for accurate cell monitoring, current sensors for charge/discharge tracking, temperature sensors distributed throughout the pack, and communication interfaces for data exchange.

Primary functions encompass state of charge (SOC) estimation with accuracy within 2-3%, state of health (SOH) monitoring to track degradation over time, cell balancing to ensure uniform performance, and protection against hazardous conditions such as overcharging, deep discharge, short circuits, and thermal runaway.

Advanced BMS implementations also provide state of function (SOF) analysis, predicting the battery's ability to deliver power at any given time—an essential feature when considering the bess meaning in high-performance energy storage systems.

The integration of these components enables the BMS to extend battery life by up to 30%, enhance safety, and optimize energy utilization in applications ranging from electric vehicles to grid-scale energy storage.

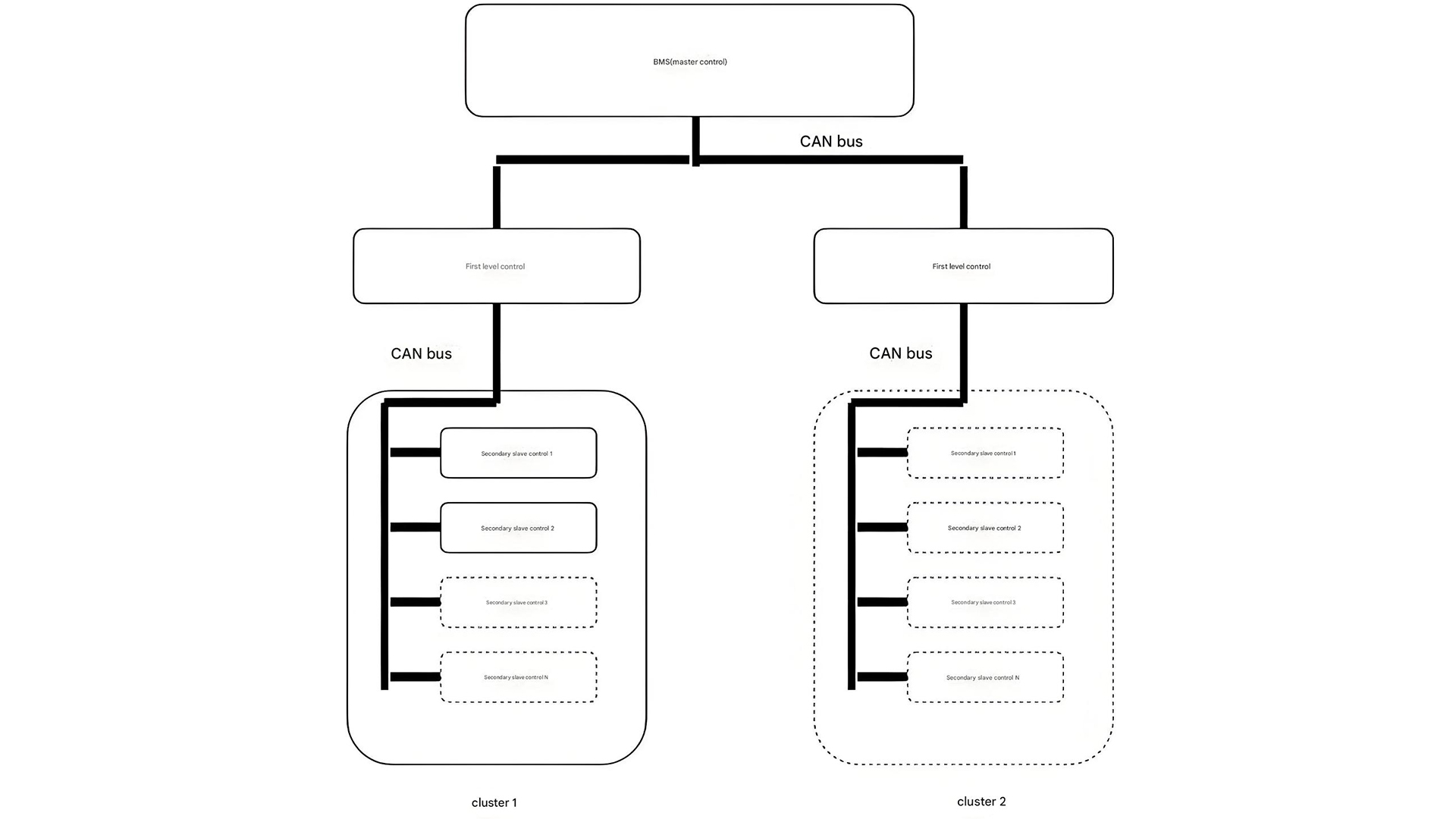

BMS Core Architecture

Diagram illustrating the integration of hardware and software components in a sophisticated battery management system, essential for understanding the bess meaning in practical implementations.

Data Acquisition Methods

Precise data acquisition forms the foundation of effective BMS operation. Modern systems employ multiple sensing technologies to capture critical battery parameters, directly impacting how we interpret the bess meaning in terms of performance metrics.

Voltage measurement is typically achieved through dedicated ADC channels with resolution exceeding 16 bits, ensuring cell voltage monitoring with accuracy better than ±1mV. This precision is vital for SOC calculation and cell balancing.

Current sensing utilizes shunt resistors for low-current applications and hall-effect sensors for high-current scenarios, providing measurement ranges from milliamps to hundreds of amps with accuracy within ±0.5% of full scale.

Temperature sensing employs thermistors, RTDs, or thermocouples strategically placed throughout the battery pack—typically one sensor per 2-4 cells—with measurement accuracy of ±1°C and sampling rates between 1-10Hz.

Advanced systems incorporate impedance spectroscopy for SOH estimation and pressure sensors for early thermal runaway detection, enhancing the comprehensive monitoring capabilities that define the modern bess meaning in safety-critical applications.

Data acquisition systems must balance sampling frequency (typically 10-100Hz) with processing capabilities and power consumption, employing filtering algorithms to reduce noise while maintaining responsiveness to critical events.

Multi-Parameter Sensing Network

Advanced data acquisition setup demonstrating voltage, current, and temperature monitoring across a battery module, a key aspect of the bess meaning in performance optimization.

Battery Pack Equalization Management

Cell equalization is critical for maximizing battery pack capacity and lifespan, addressing inherent variations in cell characteristics that emerge during manufacturing and usage—an essential consideration when evaluating the bess meaning in terms of system efficiency.

Passive equalization, the most common method in consumer applications, employs resistors to dissipate excess energy from higher-voltage cells during charging. While simple and cost-effective, it wastes energy and becomes inefficient for large packs, limiting its utility in contexts where the bess meaning implies high efficiency requirements.

Active equalization systems transfer energy between cells using inductors, capacitors, or transformers, achieving much higher efficiency (85-95%). These systems can balance cells during both charging and discharging, maintaining optimal performance across the entire operating range.

Modern BMS employ adaptive equalization algorithms that monitor cell voltages continuously and activate balancing only when necessary, reducing power consumption. Some advanced systems implement "smart balancing" that considers both voltage and capacity differences, significantly improving balancing effectiveness.

Effective equalization can increase usable capacity by 10-15% in aged packs and extend overall lifespan by 20-30%, making it a critical feature that enhances the practical bess meaning in terms of economic viability.

The choice between passive and active systems depends on application requirements, with active systems becoming increasingly prevalent in automotive and grid storage applications where performance justifies the additional cost and complexity.

Active Equalization System

Advanced active balancing circuit demonstrating energy transfer between cells, a technology that enhances the bess meaning through improved efficiency and battery longevity.

Thermal Management System

Thermal management is paramount for battery performance, safety, and longevity, as operating temperatures directly affect capacity, cycle life, and safety—key considerations in understanding the bess meaning in practical operation.

Optimal battery temperature ranges typically fall between 20-35°C, with performance degradation becoming significant below 0°C and above 45°C. Temperature gradients within the pack should be maintained below 5°C to prevent uneven aging and performance discrepancies.

Passive thermal management uses heat sinks, phase change materials (PCMs), and thermal insulation to maintain temperature within acceptable ranges without active power consumption. This approach works well for low-power applications but has limitations in high-performance scenarios where the bess meaning implies sustained high current operation.

Active thermal management employs liquid cooling/heating loops or forced air systems to actively regulate temperature. Liquid systems provide superior thermal transfer capabilities, maintaining more uniform temperatures across the pack and enabling precise control even under extreme operating conditions.

Advanced systems integrate predictive thermal modeling with real-time sensor data to anticipate thermal issues before they occur. This proactive approach optimizes cooling/heating efficiency while preventing thermal runaway—a critical safety aspect that underscores the bess meaning in risk mitigation.

Effective thermal management can extend battery life by 50% or more in demanding applications, while also maintaining 90%+ of nominal capacity across a wide range of ambient conditions.

Advanced Liquid Cooling System

Cutting-edge thermal management solution with integrated temperature monitoring, essential for maintaining optimal performance that defines the bess meaning in high-demand applications.

Data Communication System

Robust data communication is essential for BMS operation, enabling real-time monitoring, control, and integration with external systems—key aspects that define the bess meaning in interconnected energy ecosystems.

Internal communication within the BMS typically uses CAN bus (Controller Area Network) due to its reliability in noisy environments, low latency, and support for distributed control. CAN 2.0B provides data rates up to 1Mbps, sufficient for most battery monitoring applications.

For external communication, Ethernet (100BASE-TX or 1000BASE-T) is common in stationary energy storage systems, offering high bandwidth for detailed data logging and remote management—critical features when considering the bess meaning in grid-connected applications.

Wireless communication options include Wi-Fi (802.11ac) for high-data-rate applications, cellular (4G LTE and emerging 5G) for remote monitoring, and LoRaWAN or NB-IoT for low-power, long-range connectivity in distributed energy systems.

Modern BMS implement secure communication protocols with encryption (TLS 1.3), authentication, and integrity checks to prevent unauthorized access and tampering—essential security measures that protect the critical infrastructure implied by the bess meaning in energy systems.

Communication systems must balance data throughput with power consumption and reliability, often implementing adaptive data rates that increase during critical events while conserving bandwidth during normal operation.

Standardized communication protocols such as Modbus, DNP3, and OCPP facilitate interoperability with external systems, enabling seamless integration that enhances the practical bess meaning in multi-vendor energy ecosystems.

Integrated Communication Architecture

Comprehensive communication network enabling real-time data exchange, a vital component that enhances the bess meaning through system integration.

Battery Safety Management System

Safety is paramount in battery systems, with the safety management system forming the critical last line of defense against hazardous conditions—an essential component that defines the bess meaning in terms of operational safety.

Primary protection mechanisms include overvoltage protection (OVP) that disconnects the charger when cell voltages exceed safe limits (typically 4.3-4.4V for Li-ion), undervoltage protection (UVP) that prevents deep discharge below 2.5-2.7V per cell, and overcurrent protection (OCP) that limits charge/discharge currents to safe levels.

Thermal protection systems monitor temperatures across the pack, activating cooling systems at moderate thresholds (40-45°C) and initiating shutdown procedures if temperatures exceed critical levels (60-65°C for most chemistries).

Advanced safety systems incorporate gas detection sensors that identify electrolyte decomposition products (like CO, H2, and HF) which precede thermal runaway, providing early warning that enhances the bess meaning in hazard mitigation.

Isolation monitoring continuously checks for insulation degradation between the battery pack and chassis, ensuring high-resistance isolation (typically >100kΩ) to prevent electric shock hazards in vehicle and stationary applications.

Fault tolerance is achieved through redundant sensing and control pathways, ensuring that a single component failure doesn't compromise safety. Critical safety functions often implement "fail-safe" designs that default to safe states (disconnection) when anomalies are detected.

Safety management systems must comply with rigorous standards including UN38.3, IEC 62133, ISO 26262 (for automotive), and UL 94 for flammability, ensuring that the practical bess meaning encompasses comprehensive risk mitigation.

Multi-Layer Safety Architecture

Comprehensive safety system demonstrating redundant protection mechanisms, a critical aspect that defines the bess meaning in terms of operational reliability and hazard prevention.

BMS Control Strategies

Advanced control strategies are the intelligence behind effective BMS operation, optimizing performance while protecting the battery—key elements that define the bess meaning in terms of operational efficiency.

Charging control strategies vary by chemistry, with lithium-ion systems typically implementing constant current-constant voltage (CC-CV) charging profiles. Advanced algorithms adapt charging rates based on temperature, state of charge, and cell health, maximizing charging speed while minimizing degradation.

Discharge control strategies manage power output to meet load demands while preventing conditions that could damage cells. This includes current limiting during high-demand scenarios and dynamic power adjustment based on temperature and SOH—critical features when understanding the bess meaning in performance-constrained applications.

Energy management strategies optimize battery usage in hybrid systems, balancing energy storage with other power sources (like solar PV or grid electricity) to minimize operating costs and maximize system lifetime.

Model Predictive Control (MPC) is increasingly used in advanced BMS, leveraging mathematical models to predict battery behavior and optimize control actions over a receding horizon. MPC can improve performance by 10-15% compared to traditional control methods.

Adaptive control algorithms continuously learn from battery behavior, adjusting parameters as the battery ages to maintain optimal performance throughout its lifecycle. This self-optimizing capability enhances the practical bess meaning in terms of long-term value.

Fault-tolerant control strategies ensure continued operation (with degraded performance if necessary) when minor faults occur, only initiating shutdown when absolutely necessary—balancing safety with availability in critical applications.

Adaptive Control Architecture

Advanced control system demonstrating real-time optimization algorithms that enhance the bess meaning through intelligent energy management.

Typical Design Process

The BMS design process follows a structured methodology to ensure all requirements are met, from concept to production—a systematic approach that underpins the bess meaning in terms of reliable performance.

Requirements gathering and analysis form the foundation, defining performance targets (accuracy, response time), environmental constraints (temperature range, vibration), safety requirements, and compliance standards. This phase typically takes 4-8 weeks for standard applications and longer for custom solutions.

Architecture design follows, defining the hardware and software structure, communication protocols, and integration points with other systems. This phase includes trade-off analyses between performance, cost, power consumption, and reliability—critical decisions that shape the practical bess meaning in specific applications.

Hardware design encompasses schematic capture, PCB layout, and component selection, with particular attention to analog circuit design for accurate sensing and robust protection circuits. Thermal design is integrated from the beginning to ensure reliable operation under all conditions.

Software development includes low-level firmware for real-time operation, algorithm implementation (SOC, SOH, balancing), and higher-level applications for user interaction and data logging. This phase typically employs model-based design techniques to accelerate development and testing.

Verification and validation involve extensive testing at component, subsystem, and system levels, including environmental testing, EMC/EMI compliance, safety certification, and performance validation under various operating conditions—essential steps that ensure the bess meaning translates to real-world reliability.

Production ramp-up includes manufacturing process development, test fixture design, and quality control procedures. Continuous improvement processes monitor field performance and feed back into future design iterations, creating a virtuous cycle of refinement.

Systematic Design Methodology

Structured development process ensuring robust BMS solutions that embody the bess meaning through rigorous engineering and validation.

Development Trends of BMS

The BMS industry is evolving rapidly, driven by advances in battery technology, artificial intelligence, and the growing demand for energy storage—trends that are redefining the bess meaning in the context of modern energy systems.

Artificial Intelligence (AI) and machine learning are transforming BMS capabilities, enabling more accurate SOC/SOH estimation, predictive maintenance, and adaptive control strategies that optimize performance based on usage patterns. AI-driven systems can extend battery life by up to 40% compared to traditional approaches.

Digital twin technology is emerging as a powerful tool, creating virtual replicas of battery systems that enable real-time monitoring, simulation, and optimization. This technology enhances the bess meaning by enabling predictive analytics and remote diagnostics that minimize downtime.

Increased integration is a key trend, with BMS functionality being embedded directly into battery cells (cell-level intelligence) and combined with power electronics in integrated modules that reduce size, weight, and cost while improving performance.

Higher precision sensing technologies, including microelectromechanical systems (MEMS) and quantum sensors, are enabling more accurate monitoring of battery parameters at lower cost, facilitating more precise control and earlier fault detection—advancements that enhance the practical bess meaning in terms of reliability.

Cybersecurity is becoming increasingly important as BMS becomes more connected, with advanced encryption, secure boot, and intrusion detection systems being implemented to protect against malicious attacks on critical energy infrastructure.

Sustainability is driving the development of BMS that optimize battery recycling and second-life applications, extending the value chain beyond initial use and supporting circular economy principles that redefine the bess meaning in environmental terms.

The convergence of these trends is creating smarter, more efficient, and more reliable battery management systems that will enable the next generation of energy storage applications, from electric mobility to smart grids and renewable energy integration. These advanced systems rely on high-speed data communication technologies, including optical transceivers, to transmit real-time performance data across distributed energy networks.

Next-Generation BMS Technologies

Conceptual illustration of future BMS innovations that are redefining the bess meaning through AI integration and advanced connectivity.

Battery Performance Metrics vs. BMS Capability

Comparative analysis showing how advanced BMS features enhance key performance metrics, illustrating the practical bess meaning in terms of real-world performance gains.