1. Development History

What is a battery? Tracing the evolution of energy battery technology and its integration into electric vehicles from early experiments to modern innovations.

Early Experiments (1800s)

The story of the energy battery dates back to the early 19th century with the invention of the Voltaic Pile by Alessandro Volta in 1800. This was the first true chemical battery, capable of producing a steady electric current. However, it was not until the mid-1800s that batteries began to be considered for vehicle propulsion.

In 1859, Gaston Planté invented the lead-acid battery, the first rechargeable battery. This breakthrough made electric vehicles (EVs) more practical, as they could now be recharged and reused. By the 1890s, electric cars were becoming popular in urban areas, especially among women, due to their quiet operation and lack of the manual effort required to start gasoline engines.

An early electric vehicle from the 1890s

Electric vehicles were among the first practical motor vehicles, predating gasoline-powered cars in popularity.

During this period, energy battery technology was primitive compared to today's standards. Lead-acid batteries had low energy density, limited range, and were heavy. Despite these limitations, early EVs were competitive with steam and gasoline vehicles in urban environments, where their limited range was less of a concern.

Pioneering Years (1900s)

The early 20th century saw a decline in electric vehicle popularity as gasoline-powered cars became more reliable and affordable. The invention of the electric starter by Charles Kettering in 1912 eliminated the need for hand-cranking gasoline engines, making them more accessible to the general public. Additionally, the discovery of large oil reserves in Texas and other regions made gasoline cheap and abundant.

Despite this setback, research on energy battery technology continued. In the 1950s, the nickel-cadmium (Ni-Cd) battery was developed, offering higher energy density and longer life than lead-acid batteries. However, cadmium is toxic, which limited the widespread adoption of Ni-Cd batteries in consumer applications.

1970s Oil Crisis

The oil embargoes of the 1970s sparked renewed interest in electric vehicles and energy battery research as countries sought to reduce dependence on foreign oil.

NASA's Contribution

NASA played a significant role in advancing battery technology during the space race, developing lightweight, high-performance batteries for space missions.

The 1970s oil crises led to a resurgence of interest in electric vehicles and energy battery research. Governments and industries began investing in alternative energy sources and more efficient energy storage solutions. However, progress was slow due to the technical challenges of developing batteries with high energy density, long cycle life, and low cost.

Modern Era (1990s-Present)

The modern era of energy battery technology began in the 1990s with the commercialization of lithium-ion (Li-ion) batteries. Developed by John B. Goodenough, M. Stanley Whittingham, and Akira Yoshino, who later received the Nobel Prize in Chemistry in 2019, Li-ion batteries offered a significant improvement over previous technologies in terms of energy density, rechargeability, and weight.

The introduction of the Toyota Prius hybrid electric vehicle (HEV) in 1997 marked a turning point in the adoption of electric vehicles. The Prius combined a gasoline engine with an electric motor and a Ni-MH battery, offering improved fuel efficiency and reduced emissions compared to conventional vehicles.

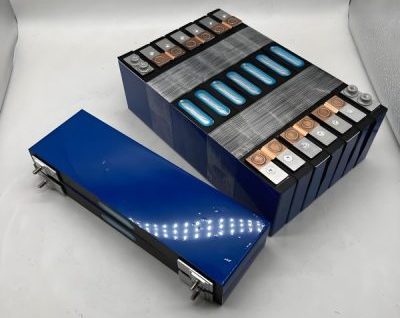

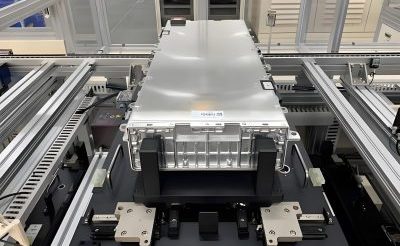

Lithium-ion battery production facility

Advances in manufacturing techniques have significantly reduced the cost of lithium-ion batteries in recent years.

The 2010s saw the rise of fully electric vehicles (BEVs) with the introduction of models like the Nissan Leaf (2010) and Tesla Model S (2012). These vehicles offered longer ranges and better performance than previous EVs, thanks to improvements in Li-ion battery technology and the construction of charging infrastructure.

Today, energy battery technology continues to evolve rapidly. Solid-state batteries, which promise even higher energy density, faster charging times, and improved safety, are currently under development and could revolutionize the electric vehicle industry in the coming years.

Key Milestones

Voltaic Pile Invention

Alessandro Volta invents the first chemical battery, the Voltaic Pile, marking the beginning of battery technology.

Lead-Acid Battery

Gaston Planté invents the first rechargeable battery, the lead-acid battery, enabling practical electric vehicles.

Electric Vehicle Popularity

Electric vehicles gain popularity in urban areas, competing with steam and gasoline-powered cars.

Nickel-Cadmium Battery

The nickel-cadmium battery is developed, offering higher energy density than lead-acid batteries.

Oil Crisis Spurs Research

The oil crises lead to increased research in alternative energy sources and energy storage.

Commercial Li-ion Batteries

Sony commercializes the first lithium-ion battery, revolutionizing portable electronics and later electric vehicles.

Toyota Prius Introduction

The Toyota Prius, the world's first mass-produced hybrid electric vehicle, is launched.

Rise of BEVs

Fully electric vehicles like the Nissan Leaf and Tesla Model S are introduced, driving the growth of the EV market.

Solid-State Battery Development

Research and development of solid-state batteries accelerate, promising to overcome limitations of current Li-ion technology.

2. Technology Status

Form Eergy: An overview of current energy battery technologies, global research trends, and key players in the development of electric vehicle batteries.

Battery Types

There are several types of batteries used in electric vehicles today, each with its own advantages and disadvantages. The choice of battery type depends on factors such as energy density, cost, safety, and cycle life.

Lithium-ion Batteries

The most common type of battery used in electric vehicles today, offering high energy density, long cycle life, and relatively low self-discharge.

Nickel-Metal Hydride (Ni-MH)

A mature technology commonly used in hybrid electric vehicles, offering good energy density and reliability, but higher self-discharge than Li-ion batteries.

Lead-Acid Batteries

The oldest and cheapest rechargeable battery technology, still used in some low-cost electric vehicles and as auxiliary batteries in hybrid and electric vehicles.

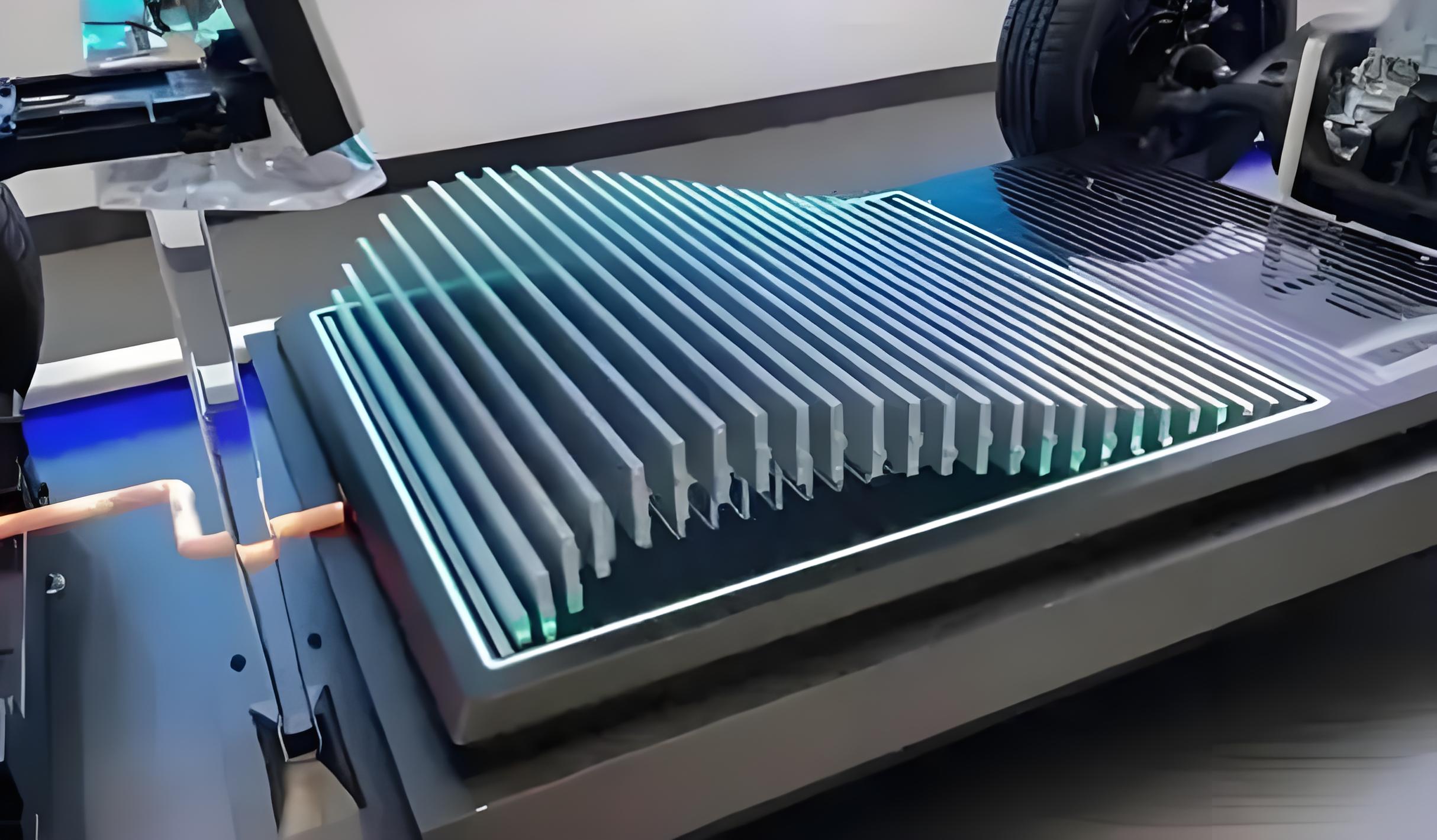

Solid-State Batteries

A next-generation technology under development that uses solid electrolytes instead of liquid ones, offering higher energy density, faster charging, and improved safety.

Key Chemistries

Within the category of lithium-ion batteries, several different chemistries are used, each with its own performance characteristics. The choice of chemistry depends on the specific requirements of the application, such as energy density, power output, safety, and cost.

Lithium-Ion Battery Chemistries Comparison

A comparison of the most common lithium-ion battery chemistries used in electric vehicles.

| Chemistry | Energy Density | Power Density | Cycle Life | Safety | Cost | Applications |

|---|---|---|---|---|---|---|

|

Lithium Cobalt Oxide (LCO)

|

High | Medium | Medium | Low | High | Consumer electronics |

|

Lithium Manganese Oxide (LMO)

|

Medium | High | Medium | High | Medium | EVs, power tools |

|

Lithium Iron Phosphate (LFP)

|

Medium | High | Very High | Very High | Low | EVs, grid storage |

|

Lithium Nickel Cobalt Aluminum Oxide (NCA)

|

Very High | Medium | Medium | Medium | Medium-High | EVs (Tesla) |

|

Lithium Nickel Manganese Cobalt Oxide (NMC)

|

High | Medium | High | Medium | Medium | EVs, consumer electronics |

Among these chemistries, NMC and LFP are the most widely used in electric vehicles today. NMC batteries offer a good balance of energy density, cycle life, and cost, making them suitable for a wide range of applications. LFP batteries, on the other hand, are known for their high safety, long cycle life, and low cost, which has made them increasingly popular in recent years, especially in China.

Major Manufacturers

The global market for electric vehicle batteries is dominated by a few major players, primarily based in Asia. These companies are investing heavily in research and development to improve battery performance, reduce costs, and scale up production.

Contemporary Amperex Technology Co., Limited (CATL)

The world's largest manufacturer of electric vehicle batteries, based in China. CATL supplies batteries to major automakers including Tesla, Volkswagen, and BMW.

LG Energy Solution

A South Korean company that supplies batteries to automakers such as Tesla, General Motors, and Hyundai. LG is known for its NMC battery technology.

Panasonic

A Japanese company that has been a key supplier of batteries to Tesla. Panasonic specializes in NCA battery technology and operates Gigafactories with Tesla.

Samsung SDI

Another South Korean company that supplies batteries to automakers including BMW, Ford, and Audi. Samsung SDI focuses on high-energy-density NMC batteries.

BYD

A Chinese company that not only manufactures electric vehicles but also produces its own batteries, particularly LFP batteries under its Blade Battery technology.

SK Innovation

A South Korean company that supplies batteries to automakers such as Hyundai, Kia, and Volkswagen. SK Innovation is also investing in solid-state battery technology.

In addition to these established players, new companies are entering the market, and automakers are increasingly investing in in-house battery production to secure supply and reduce costs. For example, Tesla is developing its own 4680 battery cells, and Ford has announced plans to build battery factories in the United States.

Global Research Trends

Research in energy battery technology is focused on several key areas, including improving energy density, reducing costs, enhancing safety, and developing sustainable and environmentally friendly battery chemistries.

Key Research Areas

Solid-State Batteries

Solid-state batteries replace the liquid electrolyte in traditional Li-ion batteries with a solid electrolyte, offering higher energy density, faster charging times, and improved safety. Companies like QuantumScape and Toyota are leading the research in this area.

Fast Charging Technologies

Research is focused on developing batteries and charging infrastructure that can support ultra-fast charging, reducing charging times to comparable levels with refueling a gasoline vehicle.

Sustainable and Low-Cost Materials

Efforts are underway to reduce reliance on scarce and expensive materials like cobalt and nickel, and to develop more sustainable battery chemistries, such as sodium-ion and lithium-sulfur batteries.

Battery Recycling

As the number of electric vehicles on the road increases, battery recycling becomes crucial to recover valuable materials and reduce environmental impact. Advanced recycling technologies are being developed to improve recovery rates.

Global R&D Investment in Energy Battery Technology (2023)

Billions of dollars are being invested globally in battery research and development.

Governments around the world are also playing a significant role in promoting battery research through funding and policy support. For example, the European Union's Battery Alliance aims to build a competitive and sustainable battery value chain in Europe, while the United States has announced plans to invest billions in battery technology research and domestic production.

3. Vehicle Types

An overview of the different types of vehicles powered by energy batteries, from passenger cars to commercial vehicles and beyond.

Passenger Vehicles

Passenger vehicles are the most visible segment of the electric vehicle market. They can be categorized into several types based on their powertrain and battery to power.

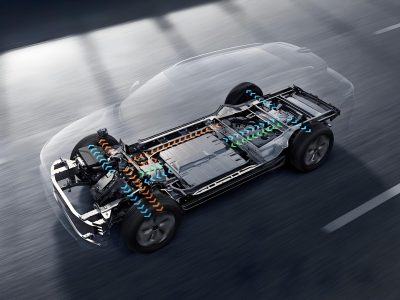

Battery Electric Vehicles (BEVs)

Fully electric vehicles that run exclusively on battery power. They have no internal combustion engine and produce zero tailpipe emissions.

Hybrid Electric Vehicles (HEVs)

Vehicles that combine a gasoline engine with an electric motor and a small battery. The battery is charged through regenerative braking and the gasoline engine.

Plug-in Hybrid Electric Vehicles (PHEVs)

Similar to HEVs but with a larger battery that can be charged by plugging into an external power source. PHEVs can run on electric power alone for a limited range.

Fuel Cell Electric Vehicles (FCEVs)

Vehicles that use hydrogen fuel cells to generate electricity, which powers an electric motor. FCEVs produce only water vapor as a byproduct.

The market share of these different types of electric passenger vehicles varies by region. In China, for example, BEVs dominate the market, while in Japan, HEVs are more popular. In Europe and the United States, there is a mix of BEVs, PHEVs, and HEVs.

Commercial Vehicles

The commercial vehicle segment is increasingly adopting electric powertrains to reduce operating costs and emissions. This includes buses, trucks, delivery vehicles, and more.

Electric Buses

Electric buses are becoming increasingly common in urban areas around the world. They offer significant advantages in terms of reduced noise pollution and emissions compared to diesel buses.

Electric Trucks

Electric trucks are being developed for various applications, from light-duty delivery trucks to heavy-duty long-haul trucks. Challenges include range limitations and high battery costs.

Electric Delivery Vehicles

Electric delivery vehicles are well-suited for urban delivery routes, where their limited range is less of a concern and their lower operating costs provide significant savings.

Electric Vans

Electric vans are popular for commercial use, such as passenger transportation and small cargo delivery. They offer a balance of range, payload capacity, and efficiency.

The adoption of electric commercial vehicles is being driven by several factors, including government incentives, lower operating costs, and the need for companies to meet sustainability goals. However, challenges such as high upfront costs, limited charging infrastructure, and range anxiety for long-haul applications remain.

Two-Wheelers

Electric two-wheelers, including motorcycles, scooters, and bicycles, are popular in many parts of the world, particularly in densely populated urban areas. They offer a cost-effective and efficient mode of transportation.

Electric Motorcycles

Electric motorcycles offer high performance and instant torque, making them popular among enthusiasts. They are also more energy-efficient and require less maintenance than gasoline-powered motorcycles.

Electric Scooters

Electric scooters are a popular choice for short trips in urban areas. They are lightweight, easy to maneuver, and require minimal parking space.

Electric Bicycles (E-Bikes)

Electric bicycles assist the rider with an electric motor, making it easier to climb hills and travel longer distances. They are popular for commuting and recreational use.

Electric Kick Scooters

Electric kick scooters are popular for short trips and last-mile transportation in urban areas. They are lightweight, portable, and easy to use.

Electric two-wheelers are particularly popular in Asia, where they are often the primary mode of transportation in urban areas. In recent years, they have also gained popularity in Europe and North America, driven by the need for sustainable and efficient urban mobility solutions.

Specialty Vehicles

Energy batteries are also used in a variety of specialty vehicles, including off-road vehicles, marine vessels, aircraft, and even recreational vehicles. These applications often require specialized battery solutions tailored to their specific needs.

Electric Boats and Ships

Electric propulsion is becoming increasingly popular in the marine industry, particularly for small boats and ferries. Electric boats offer quieter operation and reduced emissions compared to diesel-powered vessels.

Electric Aircraft

Electric aircraft are still in the early stages of development but hold promise for short-haul flights and urban air mobility. The main challenge is the low energy density of current batteries.

Electric Construction Equipment

Electric construction equipment, such as excavators and forklifts, is becoming more common on job sites. These vehicles offer reduced emissions and noise pollution in enclosed spaces.

Electric Recreational Vehicles (RVs)

Electric RVs are emerging as a sustainable alternative to traditional gasoline or diesel-powered RVs. They offer the ability to camp off-grid without generating noise or emissions.

While specialty vehicles represent a smaller segment of the electric vehicle market compared to passenger cars and commercial vehicles, they play an important role in demonstrating the versatility of energy battery technology and expanding its applications beyond traditional transportation.

4. Development Trends

Future prospects and emerging trends in energy battery technology and electric vehicle development are being redefined by innovators like our next energy (ONE), a Michigan-based clean energy leader whose breakthroughs span technological advancements, market expansion, and policy-aligned innovation.

Technological Advancements

The future of energy battery technology and electric vehicles is promising, with several key technological advancements on the horizon. These advancements are expected to address current limitations and drive broader adoption of electric vehicles.

Key Technological Trends

Higher Energy Density Batteries

Research is focused on developing batteries with higher energy density, which would enable electric vehicles to travel longer distances on a single charge. Solid-state batteries, in particular, hold promise for significantly improving energy density.

Faster Charging Technologies

Advances in charging technology, such as ultra-fast chargers and bidirectional charging, are expected to reduce charging times and make electric vehicles more convenient for consumers.

Battery Recycling and Second-Life Applications

As the number of electric vehicles increases, battery recycling and second-life applications for used batteries are becoming increasingly important. This will help reduce costs, conserve resources, and minimize environmental impact.

Smart Battery Management Systems

Advanced battery management systems (BMS) using artificial intelligence and machine learning will optimize battery performance, extend battery life, and improve safety.

Sustainable and Low-Cost Materials

Development of battery chemistries that use abundant and low-cost materials, such as sodium-ion and lithium-sulfur batteries, could reduce dependence on scarce resources like cobalt and nickel.

Another significant trend is the integration of energy storage systems with renewable energy sources such as solar and wind. This can help address the intermittency of renewable energy and create a more stable and sustainable energy grid.

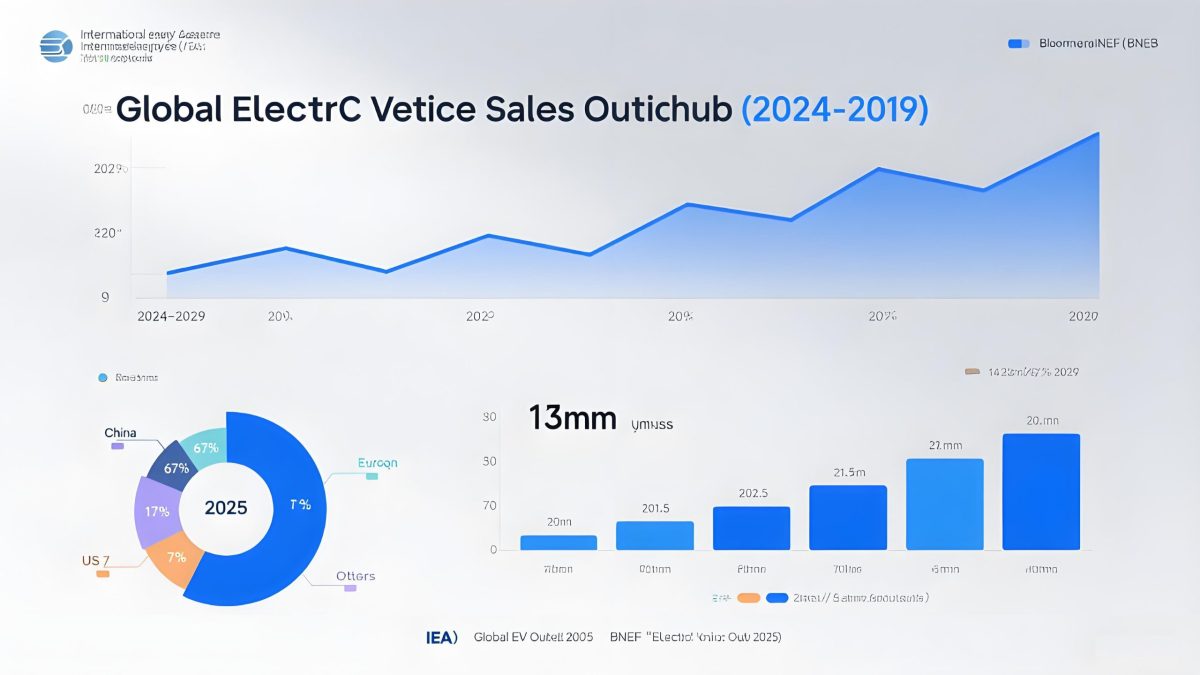

Market Growth Projections

The global market for electric vehicles is expected to continue growing rapidly in the coming years, driven by technological advancements, falling battery costs, and supportive government policies.

Global Electric Vehicle Sales Projections

The number of electric vehicles on the road is expected to reach over 145 million by 2030.

Several factors are contributing to this growth:

Falling Battery Costs

The cost of lithium-ion batteries has decreased by over 80% since 2010, making electric vehicles more price-competitive with conventional vehicles. Continued cost reductions are expected as production scales up and technology improves.

Environmental Concerns

Growing awareness of climate change and air pollution is driving consumer demand for cleaner transportation options. Electric vehicles produce zero tailpipe emissions, making them an attractive alternative to gasoline-powered vehicles.

Technological Advancements

Improvements in battery technology, including increased range and faster charging times, are making electric vehicles more practical and appealing to consumers.

Government Policies

Governments around the world are implementing policies to promote electric vehicle adoption, including subsidies, tax incentives, and stricter emissions regulations.

In addition to passenger vehicles, the market for electric commercial vehicles and two-wheelers is also expected to grow significantly. This growth will be driven by similar factors, as well as the specific needs of these segments, such as lower operating costs and reduced emissions in urban areas.

Charging Infrastructure

The expansion of charging infrastructure is critical for the widespread adoption of electric vehicles. Governments and private companies are investing heavily in building charging networks to meet the growing demand.

Types of Charging Infrastructure

Different types of charging stations offer varying levels of charging speed and convenience.

| Charging Type | Charging Speed | Typical Use Case | Charging Time for 80% | Infrastructure Requirements |

|---|---|---|---|---|

|

Level 1 (Slow Charging)

|

3-5 miles per hour | Home charging | 8-20 hours | Standard household outlet |

|

Level 2 (AC Charging)

|

10-60 miles per hour | Home, workplace, public charging | 2-8 hours | 240V electrical supply |

|

DC Fast Charging

|

100-350 miles per hour | Highway rest stops, public charging stations | 20-60 minutes | High-power DC charging equipment |

|

Ultra-Fast Charging

|

Up to 1000 miles per hour | Future high-speed charging networks | 5-15 minutes | Specialized ultra-high-power infrastructure |

In addition to expanding the number of charging stations, future trends in charging infrastructure include:

Wireless Charging

Wireless charging technology, which allows vehicles to charge without plugging in, is being developed and tested. This could make charging more convenient and seamless for electric vehicle owners.

Vehicle-to-Grid (V2G) Technology

V2G technology enables electric vehicles to not only consume energy but also return it to the grid. This can help balance grid demand, store excess renewable energy, and provide additional revenue streams for vehicle owners.

Solar-Powered Charging Stations

Integrating solar panels with charging stations can provide clean, renewable energy for charging electric vehicles, reducing their carbon footprint even further.

Smart Charging Networks

Smart charging networks use data and AI to optimize charging times and manage grid demand. This can help reduce costs, improve efficiency, and ensure that charging infrastructure is used effectively.

Policy and Regulatory Environment

Government policies and regulations play a crucial role in shaping the development and adoption of electric vehicles and energy battery technology. Around the world, governments are implementing a variety of measures to promote the transition to electric mobility.

Key Policy Measures

Financial Incentives

Many governments offer financial incentives to encourage consumers to purchase electric vehicles, such as tax credits, rebates, and grants. For example, the United States offers a federal tax credit of up to $7,500 for the purchase of a new electric vehicle.

Zero-Emission Vehicle (ZEV) Mandates

Some regions, such as California and the European Union, have implemented ZEV mandates that require automakers to sell a certain percentage of zero-emission vehicles. These mandates help drive the production and adoption of electric vehicles.

Fossil Fuel Vehicle Bans

Several countries and cities have announced plans to ban the sale of new gasoline and diesel vehicles in the future. For example, the UK has announced a ban on new gasoline and diesel cars and vans from 2030, while California has set a similar target for 2035.

Investment in Charging Infrastructure

Governments are investing in the development of charging infrastructure to support the growth of electric vehicles. For example, the European Union has set a target to install 1 million public charging points by 2025.

Emission Standards

Stricter emission standards for vehicles are encouraging automakers to invest in electric vehicle technology. For example, the European Union's CO2 emissions standards for new cars require a 55% reduction in emissions by 2030 compared to 2021 levels.

International agreements such as the Paris Agreement also play a role in driving the transition to electric vehicles. By committing to reduce greenhouse gas emissions, countries are incentivized to promote the adoption of electric vehicles and other clean technologies.Optical Transceiver.

However, policy landscapes vary widely by country and region, and the effectiveness of these measures depends on their implementation and enforcement. Coordination between governments, industries, and other stakeholders is crucial to ensure a smooth and successful transition to electric mobility.Electronic shelf labels.

Conclusion

The development of energy battery technology and electric vehicles has come a long way since the early experiments of the 19th century. Today, electric vehicles are becoming increasingly mainstream, driven by technological advancements, falling costs, and growing environmental concerns.Related Hydraulic Spare Parts.

Lithium-ion batteries have emerged as the dominant technology for electric vehicles, offering a good balance of energy density, cost, and performance. However, research continues on next-generation technologies such as solid-state batteries, which could offer even related lithium battery technology.